ADVACAM brings to the market a new range of X-ray imaging cameras that are optimized for composite material testing. Light materials such as carbon fibres, epoxies, etc. are easily revealed in a great detail. Even challenging defects such as deep laminate wrinkles, kissing-bonds, delaminations, porosity, foreign objects and micro-cracks in the soft materials can be detected with spatial resolution of 55 µm or better. Combining the sensitivity to low X-ray energy photons with the very high dynamic range of photon counting detectors creates a powerful tool for NDT in the aerospace industry, F1 and elsewhere.

Contrary to the classical X-ray imaging setups, the robotic system produced by Advacam’s daughter company, Radalytica s.r.o., gives nearly absolute flexibility of viewing angles. Therefore, these robots allow X-raying from different perspectives, to better localise defects. Moreover, robots further open possibility of using 3D imaging techniques such as computed tomography or tomosynthesis. These are methods commonly used in medical X-ray imaging, but with limited applicability on large complicated shapes. Robots help overcome this limit. The robotic systems could be used in quality control labs or built into production lines.

Showing all 13 results

-

Advanced NDT solutions from Advacam

Read more -

AdvaPIX Quad X-ray Detector

Read more -

AdvaPIX TPX3 X-ray Detector

Read more -

AdvaPIX X-ray Detector

Read more -

Radalytica 3D Robotic Imaging System

Read more -

MiniPIX EDU Small USB X-ray Camera

Read more -

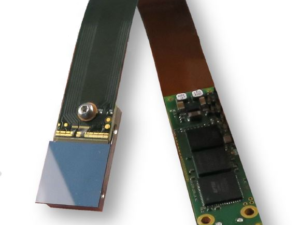

MiniPIX Small USB X-ray Camera

Read more -

MiniPIX TPX3 Small USB X-ray Camera

Read more -

MINIPIX TPX3F small flexible USB X-ray Camera

Read more -

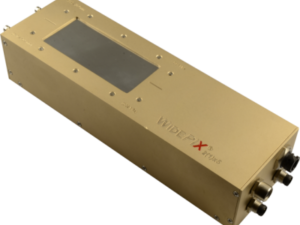

WidePIX 2(1)X5

Read more -

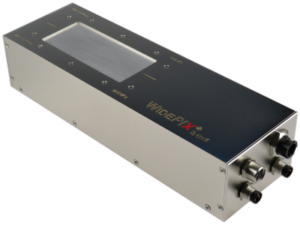

WidePIX 2(1)X5 – MPX3

Read more -

WidePIX 5X5

Read more -

WidePIX L 2(1)X15 – MPX3

Read more