Description

Cooling

One of the most important points to consider when using LEDs in machine vision is how to keep the device cool, even with modern high power LEDs. Chromasens offers a modular system for cooling.

There are two main aspects of life time:

Failure by defects of single parts

Reduction of lumens over time

The lumen maintenance of the LED is directly correlated with the temperature of the chip. If it’s possible to keep the temperature low there will be up to 80.000 hours possible. With the highest possible temperature in the LED it will be still up to 50,000 hours. Chromasens has calculated this limit back to the housing temperatures of the modules.

| Housing | 40°C | 60°C | 75°C |

|---|---|---|---|

| Soldering Point | 55°C | 85°C | 118°C |

| Lumen Maintenance | 77,000 hours | 51,000 hours | 40,000 hours |

| Years @ 250 days 100% operation | 12 years | 8.5 years | 6.7 years |

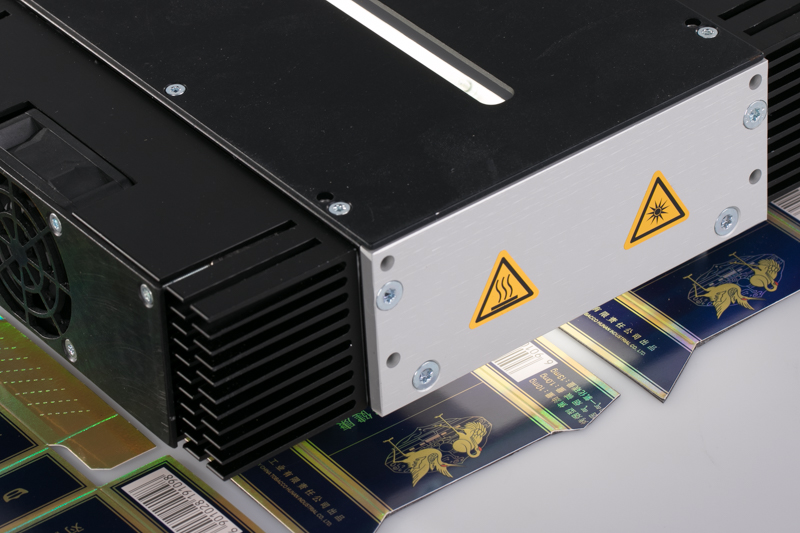

Dark field illumination

Chromasens has developed a technology to focus LEDs by using elliptical reflectors instead of using lenses. The patented reflector technology offers a unique quality for imaging and the following advantages for the customer:

- No color aberration

- Higher efficiency compared to lenses

- High power at longer working distances

lower cost & higher performance

- More defects detected (quality & quantity)

- Higher throughput

- Reduced mechanical requirements

- Environmental resistance (e.g. heat & dirt )

- Lower cost optics

- Lower maintenance costs